| Сountry of origin | Germany |

|---|---|

| Brand | SpanSet |

| Purpose | Fit most lifting applications |

| Safety factor | 7:1 |

| Main Material | PES - Polyester |

| Norms | EN 1492-2: 2000 |

| Tubing Type | Ridges |

Versatile and reliable

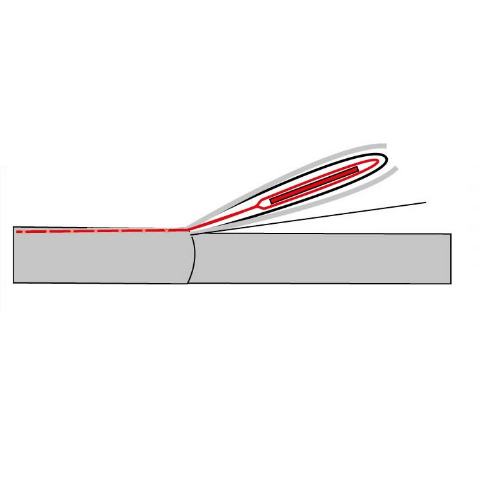

Whether it‘s a straight pull, single lift or choke: The very compact SupraPlus round sling adapts to the load with virtually no creasing. The round sling is particular slim and finds sufficient contact area even in smaller crane hooks, without being compressed. This helps to effectively prevent any unwanted loss of load capacity. Universally applicable in all sectors of industry, SupraPlus meets the highest standards in terms of safety and quality worldwide.

With reinforced fabric and textile filament

The ribbed structure woven into the outer sleeve makes SupraPlus even more resistant to wear. The ribs are made of a high-performance polyester that is markedly more cut- and wear-resistant than conventional synthetic fibres. The textile filament woven into the sleeve offers additional wear protection. Additional safety that also has economical benefits. On request, the SupraPlus can also be fitted with an RFID chip for cloud based asset management with IDXpert. An attachment loop firmly sewn onto the round sling allows for easy and quick attachment of the IDXpert RFID tag.

Additional protection

Protective sleeves such as the single-sided SF-1 and the double-sided SF-2 or SpanSet NoCut are the ideal addition. They not only effectively protect the round sling from damage, but also facilitate the turning and rotating of sharp-edged loads and generally offer protection against sharp edges.

What is it? (Product Description)

The SupraPlus roundslings are single endless lifting slings with a load bearing fibre core and outer protective sheave. They are colour coded to indicate their lifting capacity from 1 tonne to 8 tonne and can be supplied in lengths from 0.5m to 30m. Their lifting capacity has a built in factor of safety of 7:1 against their minimum breaking strength. Roundslings are lightweight and easy to handle in comparison to chainslings or wire rope slings of a similar capacity.

What can it be used for? (Intended Function)

Roundslings are a lifting accessory used to form a connection between the crane hook and the load to be lifted. These roundslings have been designed and tested to be part of a lifting arrangement. Roundslings are a versatile item of lifting equipment that may be attached by a shackle or choked directly onto the load and used to suspend the load from the crane hook. As they are endless the bearing point can be altered giving even wear along their length. Roundslings can lift smooth faced objects without damage and are ideal where a choke lift is required.

What can I use with it? (Compatibility)

This type of sling may be used with a Joker hook or bow shackle and it is recommended that the correct shackle i s ma t ched for u se wi th t he sling . This may be checked with SpanSet. The roundslings can be supplied with various protective sleeves to provide different levels of protection from damage to the sling and the load.

Who can use it? (Competence, Size and Adjustment)

All lifting operation should be carried out by a competent person who has been trained in the correct use of the equipment. If you are not sure how to correctly use your SpanSet roundsling you should contact SpanSet Training for advice.

How long will it last? (Maintenance, Inspection and Lifespan)

The product has no maximum service-life.

The condition of the product must be controlled in accordance with LOLER, this requires a thorough examination to be carried out at not more than six monthly intervals by a competent person. The competent person may impose a stricter inspection programme depending on the environment and conditions of use. A pre-use inspection should be conducted prior to each use. The lifespan may be reduced by the effects of any damage or wear and tear. All SpanSet roundslings carry unique serial numbers to enable identification for inspection and accurate traceability.

How has it been tested? (Relevant Standard and Quality Assurance)

All SpanSet roundslings are CE marked under the Machinery Directive. The CE marking process includes type testing to EN1492-2:2000+A1 – Textile Slings, Safety. The SpanSet manufacturing process is quality controlled and audited by the British Standards Institute to the international standard for quality management ISO9001:2008.

What is it made from and why? (Specification and Materials)

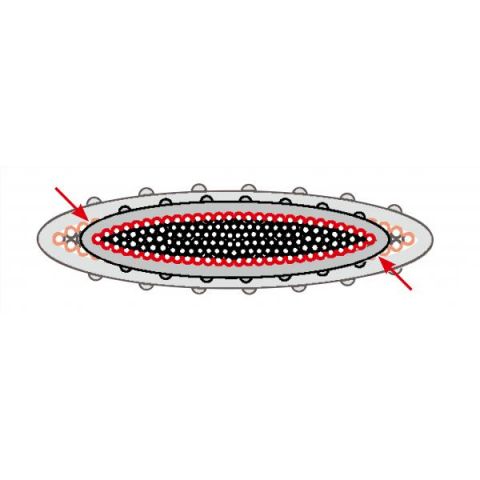

SpanSet roundslings are manufactured from a 100% polyester yarn core, wound continuously together in the form of an endless sling. The core is protected by a 100% polyester tubular sleeve. The outer sleeving is entirely non-loadbearing and serves both to protect and consolidate the polyester core. The roundsling flattens in use to provide a secure grip on the load.

Additional SpanSet SupraPlus Features

Woven-in load bearing capacity - The sling capacity is woven in to the outer sleeve so that it is always legible even in the dirtiest of conditions.

Special ribbed profile - made of high performance polyester fibre in the outer sleeve gives 3 times better wear resistance.

Compact design - narrower profile provides improved handling for smaller crane hooks.

Tough outer sleeve - the thicker outer cover includes a high tenacity yarn which provides high tear resistance and prevents any damage from growing.

Tear resistant label - label cannot be ripped out from the sling and has an additional protective sheave.

RFID – optional inclusion of an electronic tag for asset management and inspection with the SpanSet

What paperwork is supplied? (Product Records and Information)

Multilingual instructions with care and use directions. Each sling or batch of slings is supplied with a European Declaration of Conformity identifying the serial no. or numbers of the slings. This forms the ‘birth certificate’ for the equipment and should be retained. It is valid for 12 months, after which time the sling must undergo a thorough inspection. If put into use within the first 12 months the sling is subject to the 6 monthly inspections from date of first use (see overleaf).

Pocket Safe Lifting Guide – available on request, this simple to follow pocket card identifies the safe working loads under different modes of use in addition to key areas requiring inspection. The same guide is also available as a poster for the workshop.

What training is required? (Competency)

Although in itself the roundsling is a simple item to use, all people carrying out lifting operations should have the appropriate level of training. Training is available for lifting at the SpanSet training facility in Middlewich or subject to suitability on a site of your choice: Use – Training Module 1 Safe Slinging and Lifting Appreciation followed by Module 2 Practical Lifting and Slinging Beneath the Hook. Inspection and Maintenance – Training Module 1 and Module 4 Lifting Equipment Inspection & Record Keeping. All training is audited as part of our ISO9001:2008 quality management system.

Features and benefits:

- Up to four times the wear;

- Variable load bearing point for more even wear;

- Ideal for choke lifting cylindrical objects without creasing;

- Less creasing means less wear;

- WLL data woven into sleeve for unmistakable capacity identification;

- 40% thicker sleeve for durability;

- Raised ribs for greater wear and cut resistance;

- 20% narrower than standard round slings for easy hook interface;

- Lifts smooth objects without damage;

- Lightweight and soft – reduced manual handling injuries;

- High strength to weight ratio;

- Load bearing fibres protected by the outer sleeve;

- Wide choice of lifting modes;

- Tuff Tag, webbing reinforced encapsulated compliance labels;

- – Certified to AS4497.1

| Model |

Nominal lifting capacity [kg] |

Strap thickness [mm] |

Strap width [mm] |

L1 min. [m] |

L1 max. [m] |

Approx. weight per running m [kg] |

Art.№ 1,0 m |

Art.№ 1,5 m |

Art.№ 2,0 m |

Art.№ 3,0 m |

Art.№ 4,0 m |

Art.№ 5,0 m |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SupraPlus-X 500 | 500 | 4 | 38 | 0,50 |

30 |

0,20 | D005089 | D005304 | D005301 | D011621 | - | - |

| SupraPlus-X 1000 | 1.000 | 4 | 39 | 0,50 |

30 |

0,30 | D005090 | D005091 | D005092 | D005094 | D005095 | D015754 |

| SupraPlus-X 2000 | 2.000 | 8 | 40 | 0,50 |

30 |

0,50 | D004349 | D004350 | D004351 | D004353 | D005097 | D010772 |

| SupraPlus-X 3000 | 3.000 | 8 | 48 | 0,75 | 30 | 0,60 | D008795 | D011448 | D005096 | D005098 | D005099 | D010741 |

| SupraPlus-X 4000 | 4.000 | 9 | 54 | 0,75 | 30 | 0,80 | D008796 | D009396 | D008797 | D005101 | D008800 | D010746 |

| SupraPlus-X 5000 | 5.000 | 11 | 59 | 0,75 | 30 | 1,00 | D015760 | D009397 | D010413 | D010864 | D010941 | D011041 |

| SupraPlus-X 6000 | 6.000 | 11 | 68 |

0,75 |

30 |

1,20 | D011848 | D013340 | D014612 | D010330 | D012581 | D010923 |

| SupraPlus-X 8000 | 8.000 | 13 | 74 | 0,75 |

30 |

1,60 | - | D015763 | D011461 | D010862 | D011458 | D010863 |