| Сountry of origin | Germany |

|---|---|

| Brand | THIELE |

| Purpose | Lashing applications |

| Safety factor | 2:1 |

| Finish | RAL 3003 |

| Testing | 100% Magnetic Crack Tested |

| Swivel range | 150° |

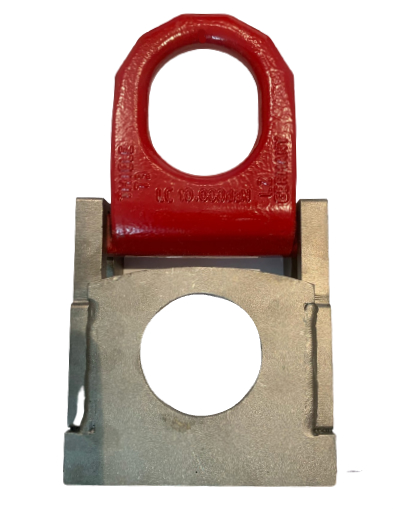

The weld-on ZK-modules TWN 1471 are predominantly installed in C-shaped side frames of low-loaders and trailers. The large swivel range also allows the securing of overhanging loads. A newly developed, patented cassette design enables a fixed mounting position for easy connection to the lashing equipment. Stressless Lashing in perfection. The manufacturing and testing requirements are based on DIN EN 1677-1.

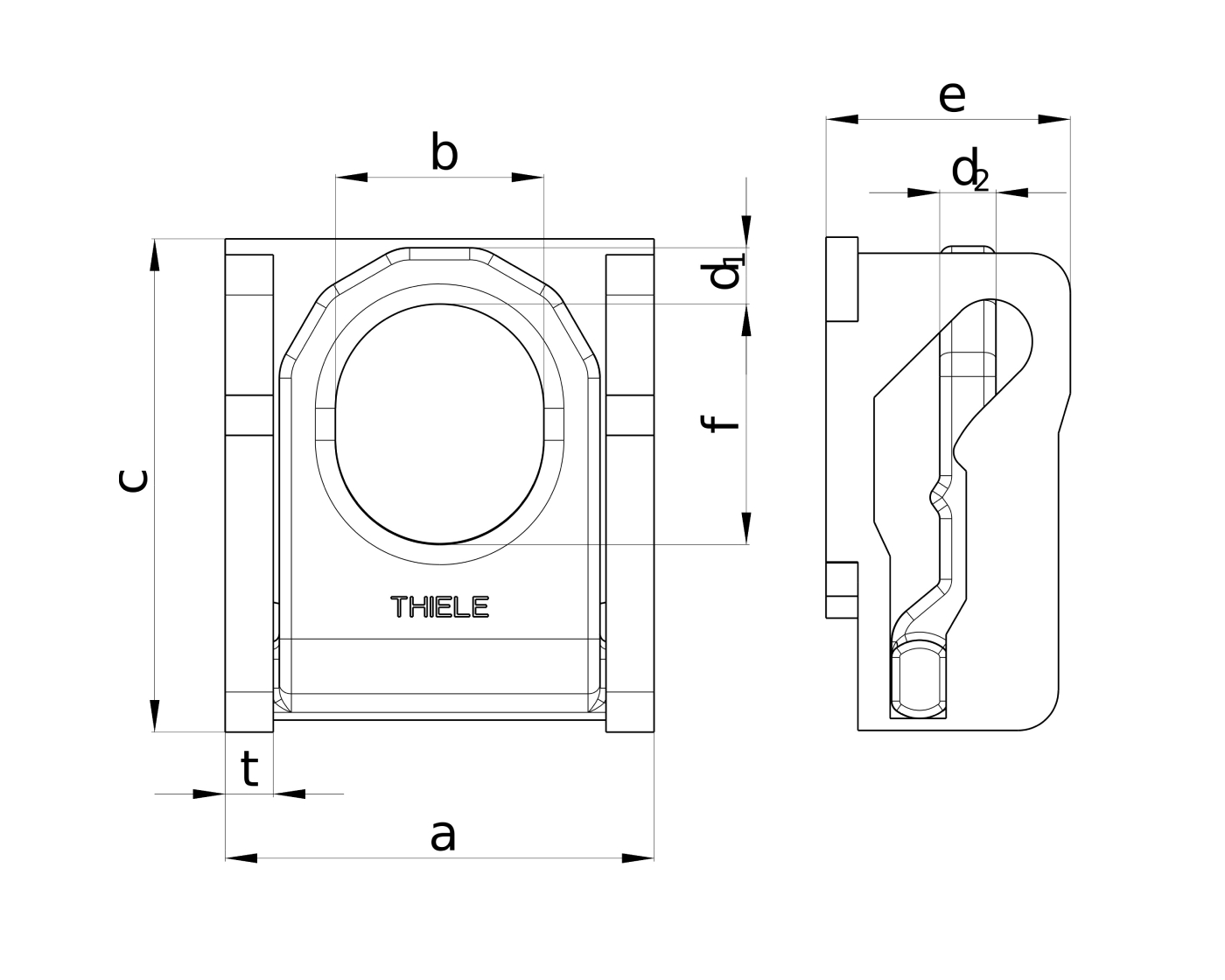

| Trade Size | Art.№ | Execution |

Lashing Capacity (LC) [daN max.] |

d1 [mm] |

d2 [mm] |

B [mm] |

A [mm] |

T [mm] |

E [mm] |

C [mm] |

F [mm] |

Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | F352390 | N | 5.000 | 14 |

14 |

52 |

107 | 12 | 61 | 119 | 60 | 2,60 |

| 5 | F352395 | S | 5.000 | 14 |

14 |

52 |

107 |

12 | 61 |

119 |

60 | 2,60 |

| 10 | F352380 | N | 10.000 | 18 |

18 |

62 |

137 |

15 | 73 | 144 | 78 | 3,60 |

| 10 | F352385 | S | 10.000 | 18 |

18 |

62 |

137 |

15 |

73 |

144 | 78 | 3,60 |

*The plates of the lashing cassette in the execution „N“ (=Normal) are produced in micro-alloyed steel. The execution „S“ (=Special) are produced from special steel and may be hot dip galvanized (up to 500°C), together with the vehicle frame.

General information

The standard DIN EN 12640 specifies the minimum testing requirements for lashing points on road trucks and trailers with flatbed bodies and a permissible total weight of more than 3,5 t for mixed cargo transportation. Lashing points are devices to attach lashing gear. A lashing point can be an oval link, hook, lug or lashing rail. These types of lashing points may lead to safety issues when in operation.

A non-appropiate dimensioning and use of non-suitable lashing points, as well as the damage of the lashing points and frames of the vehicle, shows a high potential danger in traffic. In operation, oval links are often exposed to unforeseen torque which may cause a damage to the body-work of the vehicles. Very often required inclination angles are not properly considered. Further, oval links can cause unnecessary noise exposure in traffic. The developed THIELE ZK-Modules (lashing ring with cassette) may be easily fitted and adopted at the side frames of trailers.

The ZK-Modules are marked with permissible lashing capacity (LC), manufacturer name (THIELE) and standard number (DIN EN 12640). Official agencies may easily check the correct installation. The ZK-Modules made by THIELE provides highest safety for load securing in the heavy-duty road traffic.