| Сountry of origin | Germany |

|---|---|

| Brand | THIELE |

| Purpose | Round link chains for slings |

| Material | high alloyed steel |

| Elongation at break (completed finish) | min.20 % |

| Breaking Stress | min.1000 N/mm2 |

| Component Strength | 1450-1550 MPa |

| Temperature Application Range | −30°C up to 380°C; reduction starting from 200°C. |

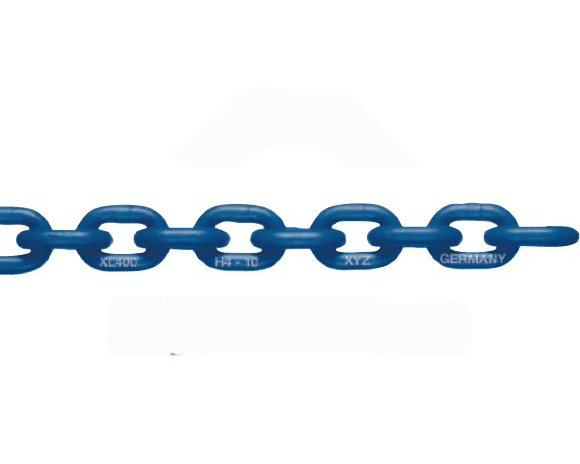

| Colour Round Steel Link Chains (AQUA lacquer) | ultramarine blue painted (RAL 5002) |

| Colour Forgings | ultramarine blue powder painted (RAL 5002) |

| Standards | PAS 1061 (Manufactures Recommendation) |

| Manufacturers Proof Force (MPF) | min.2,5 x WLL |

| Breaking Force (BF) | min.4 x WLL; up to 7% reduction allowed |

| Elongation at break (completed finish) | min.20% |

| Charpy Notch Value | min.42J at -20°C |

| Deflection | min.0,8 x d |

| Fatigue | min.20.000 LC |

| Marking | XL400; H-10, Germany, ID-Code |

The grade 100 lifting chains XL400 are made from CrNiMo alloy steel and are used to assemble chain slings and lashing chains. The max. application temperature is 380°C. The lifting chains are especially characterized by their certified fatigue strength. The manufacturing and testing requirements for these high-quality round steel chains are based on the DIN EN 818, PAS 1061 and on the German Statutory Accident Insurance test principle GS-HM 37.

Legal Marking of Grade 100 Chains by the German DGUV

The number 4 under the H represents a registration number of the German statutory accident insurance (DGUV) and helps to identify/locate the manufacturer in case of damage. The marking is also recognized by the international certification societies as well as by the work authorities ect., among others the A. I. B. in Brussels.

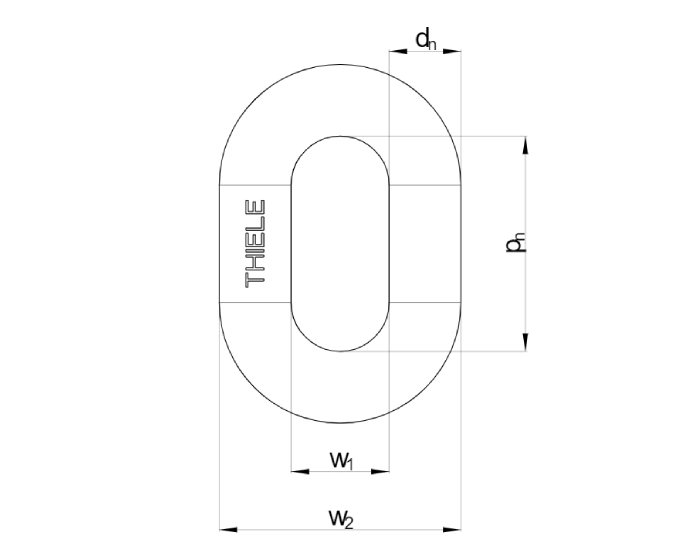

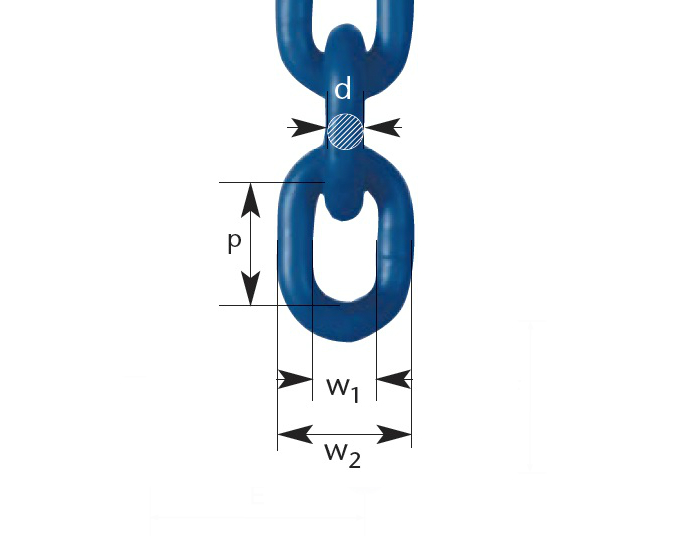

| Trade Size | Art.№ |

Working Load Limit [t max.] |

Nom. Size dn [mm] |

Tol.+[mm] |

Pitch pn [mm] |

Pitch Tol. ± [mm] |

Inside Width w1 [mm min.] |

Outside Width w2 [mm max.] |

Weight [kg/m] |

|---|---|---|---|---|---|---|---|---|---|

| 6-10 | F01610B | 1,40 | 6 | 0,33 | 18 | 0,5 | 7,80 | 22,20 | 0,90 |

| 8-10 | F01615B | 2,50 | 8 | 0,45 | 24 | 0,7 | 10,92 | 29,60 | 1,60 |

| 10-10 | F01622B | 4,00 | 10 | 0,54 | 30 | 0,9 | 13,00 | 37,00 | 2,44 |

| 13-10 | F01629B | 6,70 | 13 | 0,69 | 39 | 1,2 | 17,48 | 48,10 | 4,30 |

| 16-10 | F01635B | 10,00 | 16 | 0,86 | 48 | 1,4 | 20,80 | 59,20 | 6,25 |

| 20-10 | F01638B | 16,00 | 20 | 1,08 | 60 | 1,8 | 26,00 | 74,00 | 9,70 |

| 22-10 | F01650B | 19,00 | 22 | 1,19 | 66 | 2,0 | 28,60 | 81,40 | 11,30 |

| 26-10 | F01660B | 26,50 | 26 | 1,38 | 78 | 2,3 | 33,80 | 96,20 | 18,00 |

| 32-10 | F01670B | 40,00 | 32 |

2,20 |

96 | 2,9 | 41,60 | 118,40 | 27,00 |

Load Factor at Asymmetry

| No. of Legs | 1 |

2 |

2 |

3 |

3 | 4 | 4 |

|---|---|---|---|---|---|---|---|

| Inclination Angle ß | - | 0°– 45° | 46° – 60° | 0°– 45° | 46° – 60° | 0°– 45° | 46° – 60° |

| Load Factor | 1 | 1 | 1 | 1,4 | 1 | 1,4 | 1 |

Temperature Application Range

| Temperature Application Range | W.L.L. |

|---|---|

| -30°C to 200°C | 100 % |

| over 200°C to 300°C | 90 % |

| over 300°C to 380°C |

60 % |